Handmade Candy Canes

How Tuck’s Candy Factory creates these nostalgic pepperminty treats one cane at a time

Let’s travel back in time, about 100 years. It was a time when families gathered in their parlors to listen to newfangled radio shows such as the Grand Ole Opry, Amos ‘n’ Andy, and The Fleishmann’s Yeast Hour. The Ford Motor Company introduced the Model A to replace its popular Model T. Illustrated advertising promised housewives washing machines and vacuum cleaners that would bring meaning, delight, and cleanliness to their lives. Around this time—1929 to be precise—Walter Tuck established Tuck’s Candy Factory in Rockport, MA, kicking off nearly a century now of producing chocolates, saltwater taffy, and its special candy canes.

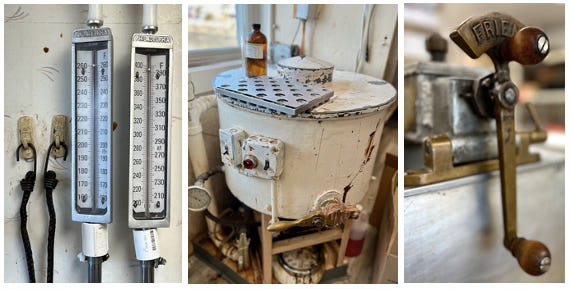

While most of the technological marvels of the 1920s have been either retired or substantially updated, Tuck’s Candy Factory carries on in many traditional ways.

In 2024, they are still making small batch candies on site, following the original recipes and deploying the equipment of yesteryear with the help of specially machined replacement parts and devoted technicians.

The responsibility of Chief Candy Man has been passed down three generations and is now held by Dan Tuck, grandson of Walter. Dan began working in the family business at age 14 doing odd jobs at the factory, which was originally located at Squam Hill. After time away from the area, Dan rejoined the operation in 2001.

Throughout the year, Dan and the crew make candies such as almond buttercrunch (Dan’s top pick), truffles, turtles, chocolate bark, chocolate-covered pretzels, nonpareils (a favorite of Palate & Palette’s staff photographer), and of course, saltwater taffy. On production days, you can watch the taffy being pulled, narrowed, kiss cut, and wrapped by a set of antique machines in the storefront.

The seasons and holidays set the rhythm to Tuck’s candy making. Valentine’s Day, Easter, and Halloween chocolates precede November and December’s handmade candy canes, chocolate-filled candy canes, ribbon candies in seven flavors, and satin sticks (which used to be called chicken bones). All year long, guests at Gloucester’s Beauport Hotel are greeted with Tuck’s chocolate starfish on their pillows.

All the holiday candies are appealing, but in my view, the handmade candy canes are most special. The “small” ones seem big and hefty compared to the mass-produced ones. They have a shiny finish and rich, pepperminty taste. Candy canes hanging on shop wires show a human touch by virtue of their slightly varied shapes, end cuts, and lengths. Each one is unique.

I wanted to know how candy canes are made and document the process to share with you, so with my staff photographer-husband in tow, we visited the factory behind the candy shop’s store at 7 Dock Square in Rockport. Dan Tuck was the main actor in the candy-cane-making performance, starting with a boiling mix of sugar and water and concluding with hand-shaped, shiny candy canes cooling on a tray.

The factory has been in its Dock Square location since the mid-1990s. The factory floor is surprisingly tiny—roughly 750 square feet—considering the output, machinery, and that the factory takes delivery of sugar one-half a ton at a time. Ingredients and finished goods compete for space. The team gets a sweet view of the Rockport harbor and its Motif No 1.

Dan matter of factly talks me through the process that he’s repeated thousands of times and that I will share in a minute. He exhibits a wry sense of humor about making candy canes over and over and over again. He reveals that the monotony is outweighed by seeing children delight in the candy canes and other special holiday confections. Dan says candy cane season is a rewarding part of his year.

Candy cane production begins mid-October and usually wraps up the weekend before Christmas.

Despite the production of 4,000 candy canes last season, Christmas Eve morning arrived and the beloved treats were sold out. Dan jumped into action and made an extra batch to avert disappointment. Those sold out quickly as well.

Dan learned candy cane production from his father Robert and has perfected it. He makes it look simple, but manipulating the candy requires many skilled moves and keen timing, which is usually driven by material temperatures.

Making a batch of about 90 candy canes clocks in at about 45 minutes.

And now, the performance begins. In less than an hour’s time, Dan, with help from team member Ben, will heat the sugar mixture, knead it, pull it, fold in the red stripe, stretch it, twist it to spiral the red stripe, cut and shape each cane, and place them on a tray to cool.

The simple recipe is not a secret.

The recipe goes like this: Heat 15 pounds of sugar, 2 tablespoons of cream of tartar, and 1 quart of water in a large copper pot until it reaches a precise 320 degrees.

Tuck’s candy canes contain sugar, whereas “store-bought” versions are made with corn syrup. Dan explains that corn syrup offers a longer shelf life and more stability so the candies are less prone to breaking. Corn syrup-based candy exhibits a hard consistency similar to a cough drop, while Tuck’s canes melt away when you put them in your mouth. Dan prefers the consistency sugar offers, plus, and this is important: It’s how they’ve always made them.

Precise thermal management is key to successful candy cane making.

Once the sugary mix reaches the proper temperature, it’s time to cool it by pouring it on to a metal cooling table. Dan sets aside a small amount of the mixture, adds red coloring, and pours that on a separate part of the table.

Next, Dan uses a scraper to lift and fold each mixture repeatedly to cool evenly. When they reach a certain firmness, Dan puts the scraper aside and dons gloves to protect his hands from the heat. At this point in the performance, the “batter” has cooled by 175 degrees down to 145 degrees. Then, he repeatedly kneads the golden-colored and red mixtures separately and presses the slabs with a metal stick to thin them out to assure even cooling.

Dan can sense when the mixture is ready for the next step, similar to how a skilled chef can tell by feel or scent when foods are cooked to the optimal temperature.

Dan’s Fun Fact: You can heat a Tuck’s candy cane with a hairdryer or in a low-degree oven, and then bend it any way you would like because of the way the sugar crystallizes. Do not Try this at home.

The manufacturing process is an energetic workout.

The next step, which is to put the batter on a hook, add peppermint flavor, and pull it, is an upper-body workout. Pulling aerates the golden sugar mixture and lightens the color so it resembles blonde Barbie hair. Dan performed this step for many years and jokes that since he climbed up the corporate ladder, he isn’t doing this part anymore. It’s where Ben steps in.

Watching the forming process is hypnotizing.

Next, Dan places the aerated mass, now looking more like a log than a loaf, on to a cloth cradle. At this point, he’s moved the log to a worktable lit with a heat lamp to keep the candy warm and pliable. Dan stretches the candy, folds it with the red stripe dough, and pulls it into a long rope.

Then comes my favorite part to watch: Dan rolls the rope laterally to add the colored spiral.

Dan uses scissors to cut the individual segments on the bias to produce a more attractive edge. Completing the process, Ben quickly picks up each pre-cane, curves the top, and then places the legitimate cane on tray. This continues about 89 more times to hit the target: 90 fresh candy canes.

You can witness the magic!

After Thanksgiving, Tuck’s Candy Factory hosts open houses on Black Friday and the four Saturdays before Christmas so visitors can observe Dan and team making candy canes, ribbon candies, and other seasonal treats. They perform about nine demonstrations a day, starting around 9:30 in the morning and concluding around 4:30 pm.

Dan says they have hosted open houses since 1996. Many visitors return year after year. Adults who visited the factory as children bring their own children to delight in viewing candy making. I might go again this year!

Dan is committed to carrying on the traditions initiated by his grandfather Walter and continued by his father Robert. He acknowledges there are machines to speed-up and even automate candy making, but he’s having none of it. Tuck’s will continue to make candy the old fashioned way, to the benefit of all its customers.

Where to find Tuck’s Candy Factory

Tucks Candy Factory, 7 Dock Square, Rockport, MA

The demonstration is a must see if you can get to Rockport during demo days. Now, exactly how does the Mars company get the candy coating on M&Ms?

Loved this story!!!! What a tribute to old-fashioned tradition and artistry! Makes me love my candy cane twice as much!!!!!